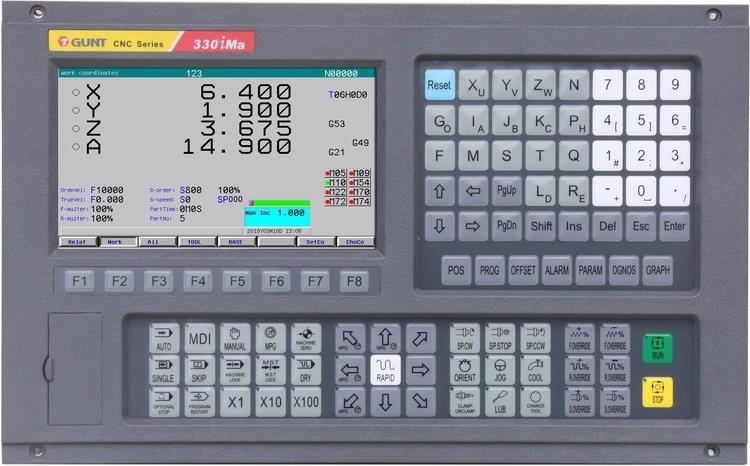

4 axis digital readout for hobby milling machine cnc controller is our new Mill CNC Control model designed specially for small budget and can maximum control 4axis , but standard configuration is 3axis . it adopts CPU with32 bits 400MHz ARM high capacity industrial grade composing a control core, and achieves the μm level accuracy motion control. It is characterized by multiple functions, stable and cost performance CNC Controller models and easy operation; Good Choice for Universal milling machine .

4 axis digital readout for hobby milling machine cnc controller | |

Motion control

| Control axes: X,Y,Z,4th(standard:3axis); linkage axes: 3axes; PLC control axes: 4axes |

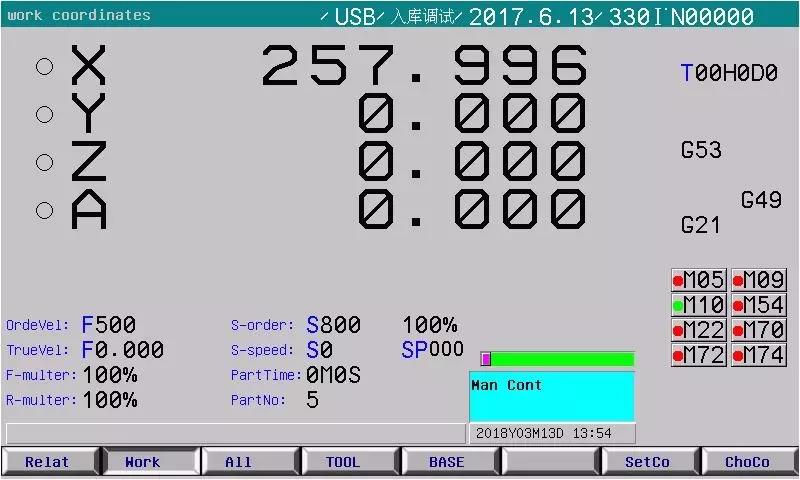

Interpolation function: X,Z two axes linear,arc and thread interpolation: X/Y two axes linear interpolation;2ms interpolation period and accuracy arrive to 1um, can set as 0.1um. | |

Position command range:-9999.999mm-9999.999mm;the minimum unit:0.001mm | |

Max.rapid traverse speed:60m/min; Max.cutting speed :30m/min | |

32-bit high performance low power industrial grade microprocessor, 400MHz CPU speed, realizing high speed , high accuracy controlling. | |

Feed rate override: 16-level real-time adjustment from 0-150% | |

Interpolation mode: linear, circular arc, thread,ellipse, parabola, rigid tapping | |

Thread function: equal pitch straight thread/taper thread/end face thread, variable pitch straight thread types and thread retraction length, angle, speed can be set. | |

Pre acceleration/deceleration: the acceleration/deceleration after interpolation can select the linear or S type, and the acceleration/deceleration time constant can be set by parameter | |

MST function | M function can be specified by address M , M function can be user-defined. |

Analog voltage output of 0v-10v in two channels ,support two spindles. Real-time adjustment of spindle rate and spindle encoder resolution can be set Adapted servo spindle can realize spindle continuous positioning, rigid and flexible tapping | |

T and 4 digits select the tool ; Tool offset value setting; Tool length compensation ;tool nose radius compensation (C type);tool wearing compensation; | |

Automatic compensation | backlash compensation,pitch error compensation;tool length compensation, tool radius compensation |

Reliability and safety | State signals: emergency stop, overtravel ,stroke limit,servo ready signal, automatic run start light signal ,automatic running signal , feed hold light signal. Self-diagnosis function: signal abnormity, system abnormity,servo abnormity, position control abnormity, spindle abnormity and so on. NC alarm:program error, operation error, overtravel error, servo error, PLC error, memory error |

Operation function | Operation mode: edit, auto, MDI, machine zero return,MPG/step, Manual ,DNC,single block,Dry run, MST lock, orogram restart, MPG interruption, step interruption,Manual interruption; Machine lock, interlock , feed hold ,cycle start, emergency stop, external reset signal .external power ON/OFF.Program zero-return, Multi-level operation authorization management |

Display | 8 inch 800x480 TFT LCD display unit ;Display in Chinese/English language |

PLC function | PLC ladder being displayed on-line and monitored in real time;PLC alarm ; Open PLC,supplying secondary PLC software development; built-in 48x32 IO ports and I/O real-time diagnosis ,users can edit IO logic to meet different requirements.: |

Communication DNC/USB function | support RS-232 serial port, USB and network interface , can realize data transfer, DNC machining and USB on-line machining function |

Optional drive unit | GT Series digital AC servo drives or 17bit/23bit absolute servos |

Chengdu Soteng CNC Technology Co., Ltd.

- Phone: +86 028-86623586

- Business Type: Manufacturer

- Location: China

- Main Products: CNC350iTa High Quality Computer Numerical Control 2 Axis Lathe CNC Controller

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: