Product Description

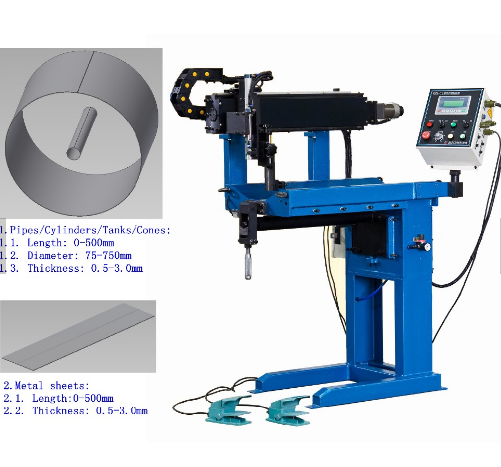

500mm Automatic longitudinal seam welding equipment / length seam welding machine / welding lathe

Universality:

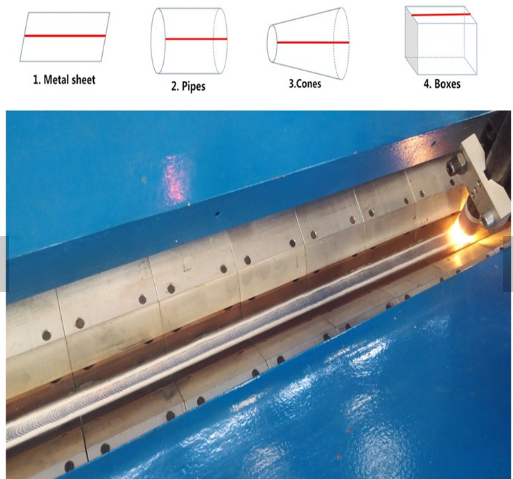

1. Can be used for TIG/MIG/MAG/PAW/SAW welding applications.

2. Can be used to weld Metal Sheets/Pipes/Cones/Boxes.

3. Can be used with Oscillator, Seam Tracker, Wire Feeder and other Function parts

Standard Components:

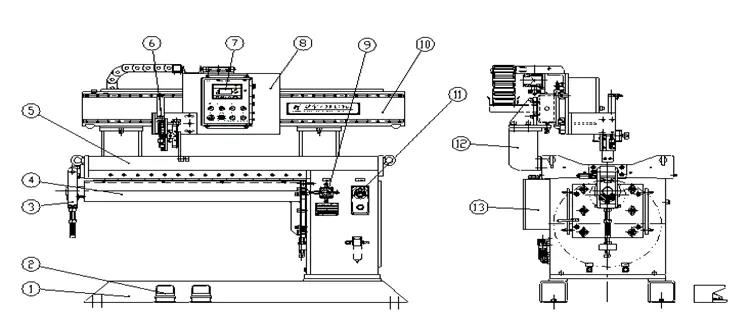

1. Base: The base is made from a rigid tube steel structure which provides stability and safety during operation. The base is equipped with mounting holes to ensure stability of the equipment on uneven surfaces.

2. Foot switches: These switches run the entire length of the base. When facing the front of the seam welder. The switch closest to the operator controls the front bank of clamping fingers. The switch next in line controls the rear back of clamping fingers. The third switch controls the rear clamping fingers only. To activate one of the switches. Merely touch the switch with your toe. This will either clamp or unclamp a bank of clamping fingers.

3. Latch: Holds the end of mandrel.

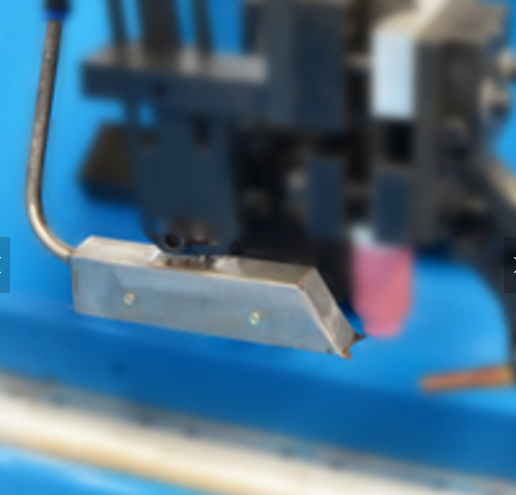

4. Mandrel: The mandrel is mounted to the mainstay and is typically round, but can be designed to meet the demands of application. The mandrel must support the part’s weight, along with supporting the clamping forces exerted by the clamping fingers. In most cases, the mandrel is designed to be supported at the mainstay and the latch end. If water cooling option and shield gas option is required, both the two parts can be mounted on the mandrel.

5. Tabletop: The tabletop houses the two banks of clamping fingers, and supports the side beam track and carriage. One of the most outstanding features of the tabletop design is the ability to view the weld in progress via the naked eye (with weld shield) or with a video camera.

6. Welding torch adjusting device: Pneumatic lifting device (Y direction), manual 2-D (Y, Z direction) adjusting device.

7. Control box: Welding control system.

8. Carriage: As a support for torch holder and control box, driven by motor, move along the side beam for automatic longitudinal seam welding.

9. Pneumatic centring valve (option):Aligning the seam/edge before welding.

10. Guide beam: As a support with guide rail for carriage.

11. Pressure gauge: Adjust pressure force for clamping fingers

12. Track support: Support the guide beam and other parts on it.

13. Junction box.

Item | Unit | ZF-500 | ZF-1000 | ZF-1500 | ZF-2000 | ZF-2500 | ZF-3000 |

Max. workpiece’s length | mm | 500 | 1000 | 1500 | 2000 | 2500 | 3000 |

Workpiece’s diameter | mm | 80-750 | 115-700 | 155-700 | 185-700 | 220-700 | 250-700 |

Workpiece’s thickness | mm | 0.5-3.0 | 0.5-6.0 | ||||

Torch stroke(pneumatic) | mm | 100 | |||||

Torch adjustment | mm | Y:± 30mm; Z: ± 30 mm | |||||

Power input | V | AC 1 Phase 220V(±10%) 50Hz | |||||

Carriage travel speed | mm/min | 100 - 1800 | |||||

Max. welding current | A | 500 | |||||

Weight | Kg | 500 | 1200 | 1500 | 1800 | 2100 | 2400 |

Package | CBM(m³) | 2.97 | 5.17 | 7.00 | 8.84 | 10.68 | 12.51 |

Options:Intergrated wire feeder,seam aligning device,different backing bars,backing bars cooling device,backing bar's gas shielding device,shielding cove

Chengdu Hanyan Technology Co., Ltd.

- Phone: +86 028-84216701

- Business Type: Manufacturer

- Location: China

- Main Products: Longitudinal seam welder,circumferential welding lathe,Resistance welding equipment,Auto parts welding machine,Welding robots

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: