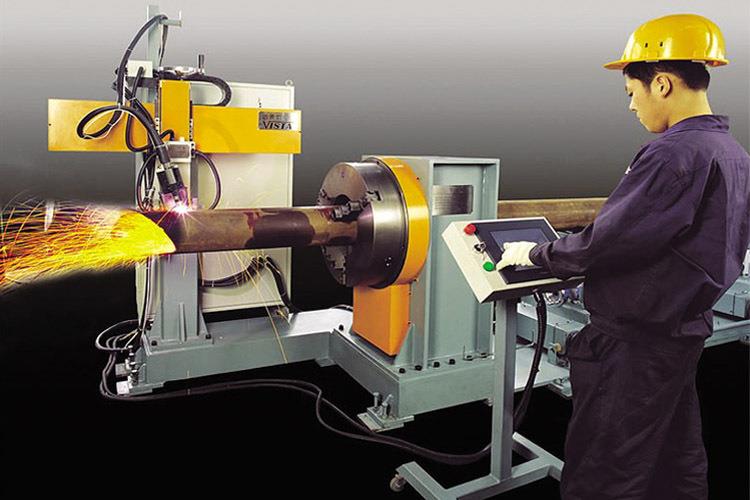

Features:

1) It is controlled by CNC automatically, and will complete the whole processing automatically with high efficiency once input the relevant data.

2) High precision, the error of positioning and cutting is only±1mm

3) Plasma cutting with three axes linkage.

4) Almost 8-10 times effective of the handwork, with much more excellent precision and quantity, and will not be effected with the welder's ability for it's reliable quanlity.

The comparison between automatic cutting and manual cutting is listed in the following table:

Automatic cutting | Manual cutting |

Input data | Following the BS5135 pipe welding instruction |

Automatic cutting | Setting out the saddleback type intersection line on the thick paper by 1:1 and cutting off the saddleback type outline on the thick paper, then we cover the outline on the ends of the pipe to mark according it and cut the pipe. |

Needing to 815 minutes for the whole process | Needing to 1.52 hours for the whole process

|

Cutting precision :±1mm | Cutting precision:±3mm |

Technical parameter:

Subject | Main parameter |

Range of diameter of pipe (mm) | Φ60--Φ600 |

Range of thickness of pipe wall (mm) | Air-plasma cutting2.325 Need to drill hole first: 17~25mm |

Length of work piece (mm) | 600--12000 |

Max weight of work piece (kg) | 5000 |

Number of axis | 6 axis |

Diameter of chuck via hole( mm) | φ310 |

Max rotating speed(r/min) | 8 |

Moving distance(left and right)mm | 12000 |

Moving speed (left and right) (mm/min) | 10000 |

Moving distance(up and down)mm | 410 |

Moving speed(up and down) (mm/min) | 5000 |

distance of cutting torchmm | 70 |

Swing angle of cutting torch | ±60° |

Champing way of work piece | 3 clutches to champ the chuck,and champ manually |

Way of cutting | Air-plasma cutting |

Crossed angle of cutting | Min 20º Max 160º |

Divided edge angle of steel tube | Min 30 º Max 150 º |

Total power of machine(kw) | ≈35 |

RF Plasma Source | OTC D-12000 |

Pressure of compressed air (MPa) | 0.4--0.6 |

Overall dimension of machine(L×W×H)mm | 14000×2000×2300 |

Weight of machine (kg) | ≈6500 |

Usage:

CNC Pipe Cutthing Machine is used for the automatic cutting in the junction of the pipe ends. It is widely used in the fields of shipbuilding, chemical industry, petroleum, mechanism, metallurgy, water conservancy, power generation, gymnasium, building installation, tube-type frame structure etc for the cutting of pipe components.

Chengdu Vista CNC Manufacture Co., Ltd.

- Phone: +86 028-87077062

- Business Type: Trading Company

- Location: China

- Main Products: CNC Plasma Pipe Cutting Machine CPM600

- Total Employees:100-500 people

- Year Established:

- Export Markets:

- Total Annual Revenue: