YH CTP880 THERMAL CTP PLATE PROCESSOR

Automatic plate rectifying,cleaning,wishing,gunmming,drying and keeping after printing,facilitates for over-printing and saves large capiatls and time.

1. Exquisite Design and Enduring Duralumin Material

Built with highly acid-resistant duralumin materials and PVC tank inside,YH thermal CTP plate processor is designed with long operation life.

2. Precise Electronic Controls

Equipped with Precise Siemens PLC control, YH thermal CTP plate processor operates the develop-wash-gum-dry process smoothly without any letup.

3. Easy Operation and Maintenance

YH thermal CTP plate processor can be connected to most thermal CTP brands and operates online or offline. Suitable for most brands 0.15 mm - 0.4 mm thermal plates. Convenient access to all serviceable components.

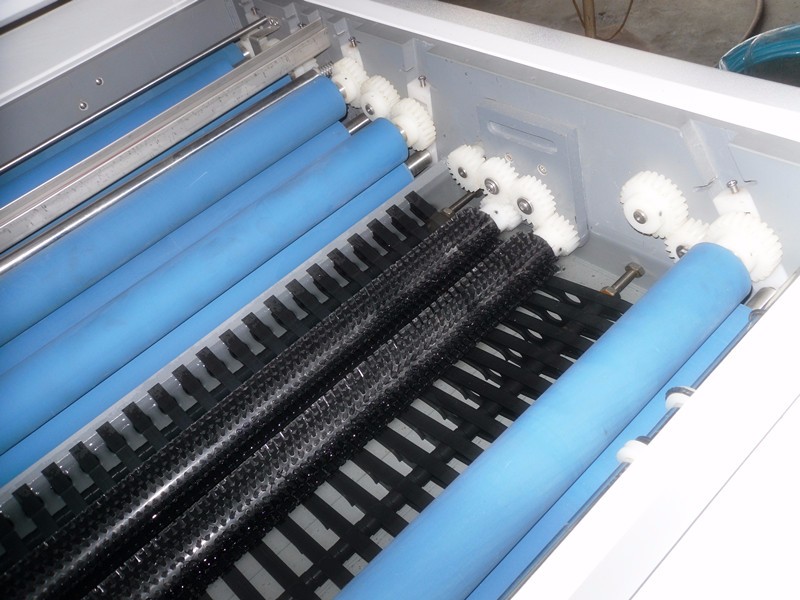

4. Superior Plate Developing Performance

Developing processing roller assures no damage to the plate surface and two sets of brushes assures sufficient development to the plate in YH thermal CTP plate processor. Equipped with automatic anti-oxidation detecting and replenishing system, YH processors accurately control developer concentration.

5. Independent Cooling System

Independent cooling system on YH thermal CTP plate processor keeps the developing temperature fluctuation within 0.5 degree Celsius.

6. Environmental Friendly

Gumming process with automatic cleaning and recycling function. Energy saving and environmental friendly.

Max.plate.width | 880mm | 1200mm |

Drying temp | 30°C-60°C | |

Min.plate.length | 400mm | |

Plate.thinckness | 0.15-0.4mm | |

Process speed | 25-60s | |

Power supply | 1φ/AC22V/30A | |

Cleaner Capacity | 35L | 50L |

Net weight | 380Kg | 560Kg |

Sichuan Culmination Printing Supplies Co., Ltd.

- Phone: +86 028-66459849

- Business Type: Trading Company

- Location: China

- Main Products: eyelet machine 40mm

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: