Manufacture Basement of Enameled Sheet Tank for Biogas Digester

Who are we

Chengdu AMOCO Architecture Engineering Company comes from AMOCO Group, which was founded in 1982 in Singapore. In 1999, AMOCO started to design, manufacture & sell the membrane products and Projects.

Overseas market:

In a few years, our business has already spread into Italy, Finland, Israel, Turkey, India, Malaysia, Indonesia, Philippine, Korea, North Korea, Thailand, Pakistan, etc. Our technology of membrane biogas holder has reached and exceeded international industry level.

Our Brand:

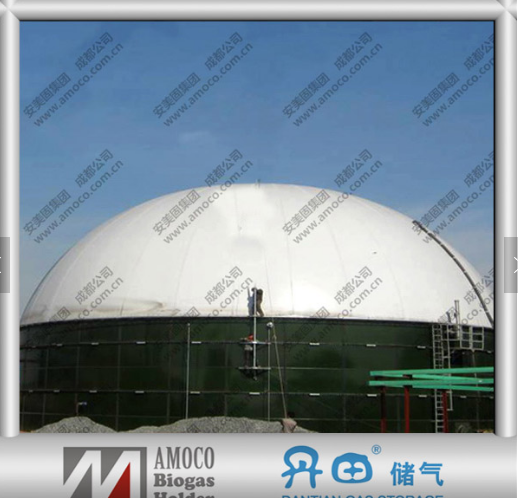

AMOCO Enameled Sheet Tank for Biogas Digester:

The first Chinese hot-rolled sheet that was double-side enameled was born in;

A famous and professional supplier to the enameled bolted tank is growing up in;

Supplier of all biogas equipment;

AMOCO Enamel Sheet Basic Properties

Coating Color | The standard color is dark green, also can be customized | |

Coating thickness | Double side, 200-450 microns | |

Plate thickness | 2 ~ 10 mm | |

Service Range | Normal | PH Value: 3 ~ 11 |

Special | pH Value: 1 ~ 14 | |

Adhesion | 3.450N/cm | |

Elastic | Same as the steel sheet, about 500kN/mm | |

Hardness | 6.0 Mohs | |

Service Life | More than 30 years | |

AMOCO Enameled Sheet Tank Installation

Enamel assembled tank is assembled by special steel plates, dedicated sealing materials, self-locking bolts, etc. Service life can up to 30 years. After pretreatment, the inside and outside of the special steel plate were coated with enamel coating, after heating, it forms very strong adhesion strength between the coating and the steel plate.

The protective coat can prevent corrosion, can withstand strong acid and alkali, has strong resistance to wearing. The steel plates lapped mutually, use self-locking bolts connection and dedicated sealing materials, this reached to the requirement of swiftly and low power installation.

AMOCO Enameled Sheet Tank for Biogas Digester:

The first Chinese hot-rolled sheet that was double-side enameled was born in;

A famous and professional supplier to the enameled bolted tank is growing up in;

Supplier of all biogas equipment;

AMOCO Enamel Sheet Basic Properties

Coating Color | The standard color is dark green, also can be customized | |

Coating thickness | Double side, 200-450 microns | |

Plate thickness | 2 ~ 10 mm | |

Service Range | Normal | PH Value: 3 ~ 11 |

Special | pH Value: 1 ~ 14 | |

Adhesion | 3.450N/cm | |

Elastic | Same as the steel sheet, about 500kN/mm | |

Hardness | 6.0 Mohs | |

Service Life | More than 30 years | |

AMOCO Enameled Sheet Tank Installation

Enamel assembled tank is assembled by special steel plates, dedicated sealing materials, self-locking bolts, etc. Service life can up to 30 years. After pretreatment, the inside and outside of the special steel plate were coated with enamel coating, after heating, it forms very strong adhesion strength between the coating and the steel plate.

The protective coat can prevent corrosion, can withstand strong acid and alkali, has strong resistance to wearing. The steel plates lapped mutually, use self-locking bolts connection and dedicated sealing materials, this reached to the requirement of swiftly and low power installation.

Chengdu Amoco Architecture Technology Co., Ltd.

- Phone: +86 028-85431144

- Business Type: Manufacturer

- Location: China

- Main Products: Membrane Gas Holder,Membrane Gas Storage Tank,Membrane Gas Storage System,Biogas Container,Membrane Gas Roof

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: