Comparing with refiner, ball grinder has been improved with the advantages of low energe consumption, high productivity, low noise, super low metal content, easy to clean, one-touch operatioin, etc. In this way, it has shortened 8-10 times of grinding time and saved 4-6 times of energy comsuption. With leading advanced technology and imported accessories with original packing, equipment performance and products’ quality is guaranteed.

Brief Introduction:

1.Granulated sugar can directly been grinded. ( Currently, enven some of the imported ball grinder can only grind powder sugar.) It tastes even better for grinded granulated sugar, and 99.99% of 8-25 microns fineness after grinded.

2.With advanced technology in the world, and imported original parts, equipment performanc and products’ quality is guaranteed. It also greatly reduces the noise, saves energy,as well as improves the production efficiency. Generally,it is maintaince-free.

3.Compared with foreign equipment, our machine only needs 5 HP water cooler, while 20 HP for some of foreign ones. Technically speaking, the abradability of steel ball is improved, so the working life is lengthened. What’s more, recycle grinding makes chocolate more tasty and greatly shorten refining time or even escape refining stage, which is what the foreign ball grinders can not do.

4.It is combined with heavy-duty loading and grinding, which ensures the high quality grinding result.

5.It is easy to operate this machine.It is equipped with full set of imported fully automatic PLC. It only takes a few days training even for new staff to get all the operation knowledge. Only 1-2 staff/shift for each equippment is needed.

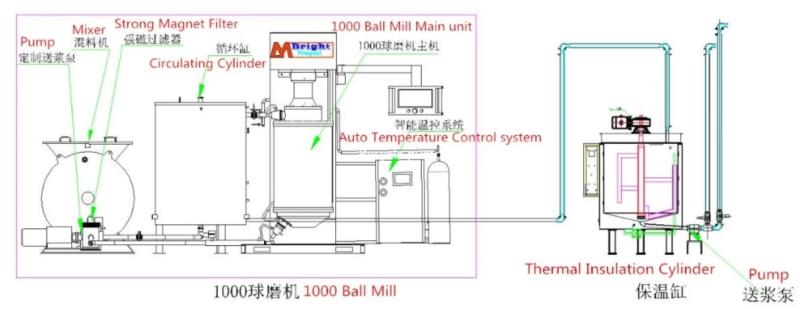

1000 Ball Grinder Parmeters:

Motor Power of Mixer Tank :5.5kw

Main Motor Power:55KW

Chcolate Pump:3KW

Motor Power of Circulation Tank:1.5KW

Water-Cooling Machine:5P, total power 4.8KW

Electrical Heating Power:2.5KW*6=15KW

Total Power:85KW

parts:

Main Unit for 1000 Ball Grinding Machine: 2400(L)*1500(W)*2600(H)mm

1000 Circulation Tank: 1400(Diameter)*2000(H)mm

1000 Mixer Tank: 2350(L)*1200(W)*1600(H)mm

5P Water Cooler: 1100(L)*650(W)*1500(H)mm

Electrical Control Cabinet: 850(L)*550(W)*2200(H)mm

Remarks: Main Unit could be placed according to customers’needs

Item | Product Name | Model | Remarks | |

1000 Ball Grinder | Ball Mill main unit | 1000 | 1unit | 304 stainless steel, PLC controller, Bearing Belt Electrical Motor |

Mixer Tank | 1000 | 1 unit | 304 Stainless Steel | |

Circulation Tank | 1000 | 1 unit | 304 Stainless Steel | |

Slurry Pump | 50 | 1 unit | 316 Stainless Steel, Customization | |

Strong Magnetic Sucking Machine | 1unit | 304 Stainless Steel | ||

Water Cooling Machine | 5P | 1 unit | ||

Pipes | Φ51 | 1set | 304 Stainless Steel | |

Product Name | Parameters | Qty | Remarks |

Electrical Valve | 24V,4cm Normally closed valve | 1 | These accessores are inluded in the accessories pack. |

Electrical Valve | 24V,1 inch Normally closed valve | 1 | |

Heating Pipe | Lenth 140cm,1.5 inch | Always stand by | |

Water pump | 220V,Diameter:4cm | 1 | |

Water pump | 220V,Diamete:6cm | 1 | |

Temperature Probe | Pt100,L-60,WZP-270 | 2 | |

Rotating Joint | 1.5 inch | 1 |

Requirements for Buyers

1.Sketch of Vacant Land as Reference.

2.Total Power of Matching Electrical Cord as Reference.

3.One Water Supply Pipeline Valve

4.One Drain Outlet ( if possible)

5.Steam Pipeline

6.One Forklift with carrying capacity of 5 tons, as well as argon arc welding equipment( for filed welding to termpring tank).

7.2 maintaince or operation staff for assisting installation and debugging.

8.After installation, appoint one staff with high sense of responsibilty for training, then sign at the end of training.

9.Provision of accomodation while in the period of installation.

Chengdu LST Science And Technology Co., Ltd.

- Phone: +86 028-87395367

- Business Type: Manufacturer

- Location: China

- Main Products: full-automatic chocolate depositing machine,oatmeal chocolate molding machine,

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: