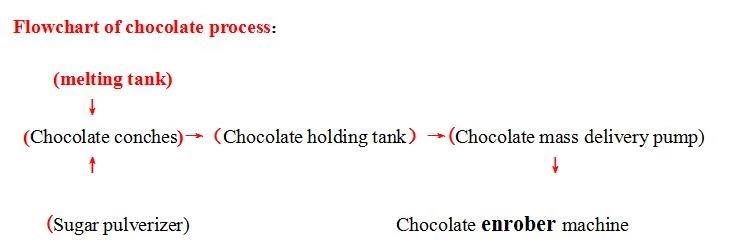

Hot sale Chocolate Enrobing Machine with Cooling Tunnel Chocolate enrober Chocolate Coating Machine

hocolate enrobing line is to coat chocolate on various food such as biscuit,wafers,egg rolls,

cake pie and snacks etc. Cooling tunnel is available. The following devices are optional also.

1.Material feeder, to simplify the feeding of biscuits or wafers etc to the enrobing wire mesh .

2.Granular sprinkler, to sprinkle sesame or peanut granular on the enrobing products

3.Decorator, to decorate zigzags or stripes of different color on the surface of enrobing products

4.High duty executions with machine lengths ranging form 1.4m to 4m and equipped with two or more coating stations ,blowers and wire belt shakers

5.Installations which have to process vicious or thixotrophic chocolate continuously,can be equipped with a mechanical chocolate return system on request dropping off chocolate will not build up anymore ,but will be returned automatically into the storage tank

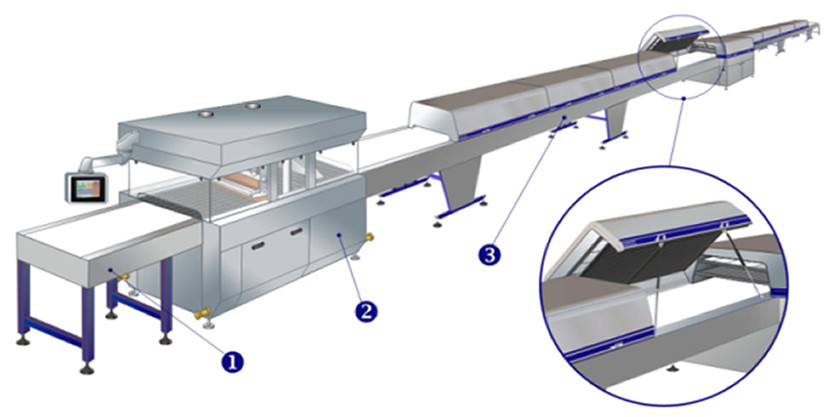

Chocolate Enrobing Machine

Features

1.Removable chocolate storage tank, making it easy to clean and refill.

2.The enrobing head, with single or double curtain type, is adjustable both longitudinally and transversely, which makes it easier to remove for rinsing.

3.Stated diameter of air channel, the wind-blow nozzle is removable, and air volume can be adjusted by the guide plate.

4.The mesh belt vibrator, with the unique horizontal support design, is used for vibration equilibrium on the product surface.

5.The enrobing machine head is equiped with hot lamps

6.Mechanical chocolate reverse-flow system makes it possible for dropped chocolate returning to storage tank, instead of piling up.

Chocolate Cooling Tunnel

With contact cooling on the base and convection cooling form above,optimum setting is availbale for any products.

The cooling module

1. Fully clad and insulated, no cold bridges

2. Optimum setting

3. Air flitter and water separator are standard

4. Either with integrated cooling compre LST or modulating system for cold water

5. Air drying with electrical air heating or dehumidifier as an option

Belt drive base plate

Sanitary design for the belt drive pedestal. the geared motor is directly attached, therefore no maintenance is required.

1.Each tunnel have two independent cooling area.

2.All-dimensional insulation, insulation cover

3.Automatic belt deviation rectification device, American Valley water chilling unit

Device | Belt width | Belt speed | Total power | Dimension (outside) | Weight(kg) |

LST-600E | 600 | 0-8m/min | 16KW | 1800mm*1100*1600 | 650 |

LST-900E | 900 | 0-8m/min | 16KW | 2400mm*1550*1800 | 1000 |

LST-1000E | 1000 | 0-8m/min | 16KW | 2600mm*1700*1800 | 1100 |

Chengdu LST Science And Technology Co., Ltd.

- Phone: +86 028-87395367

- Business Type: Manufacturer

- Location: China

- Main Products: full-automatic chocolate depositing machine,oatmeal chocolate molding machine,

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: