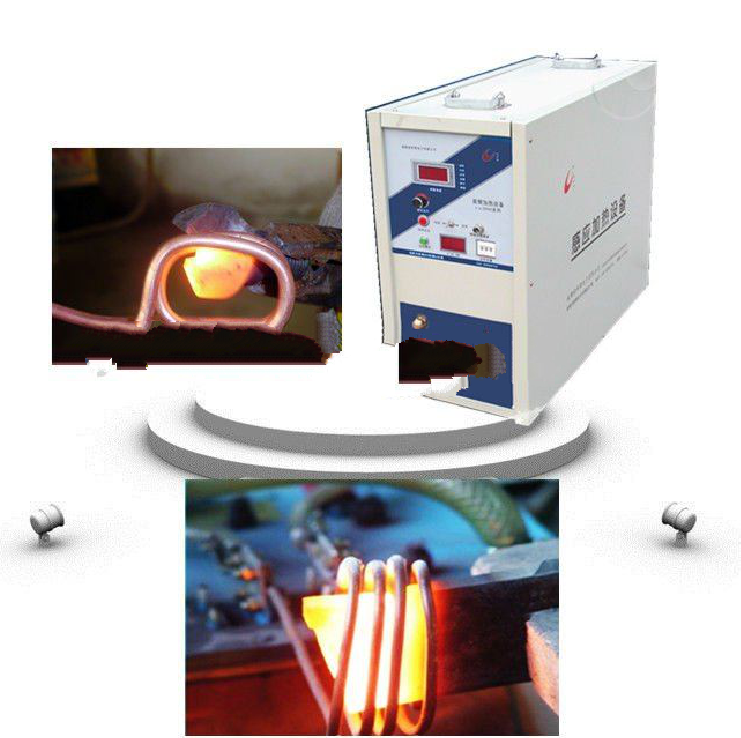

pipe bending machine price

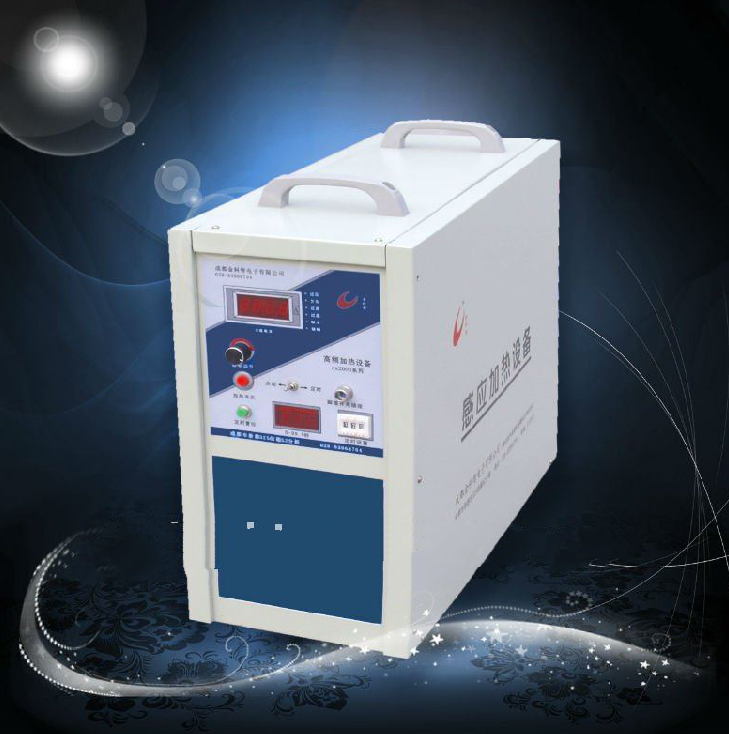

Product description:

IGBT (SIEMENS) technology, high conversion efficiency; Energy saving 15%-30% , compared to SCR/KGPS technology

Much more efficient than gas-fired and coal-fired method

100% start-up success rate; power factor > 95%

Perfect and complete protection functions, increasing machine's reliability & stability

No special foundations required, Low operating cost, Easy operation

Modular design, ease of maintaining and repairing

Application range:

1. Heat treatment of metals: hardening, tempering, and annealing.

2. Heating prior to deformation: forging, swaging, upsetting, bending, and piercing.

3. Brazing and Soldering: brazing of steel, brass, and copper to each other in combination and aluminum to aluminum.

4. Shrink fitting: In any manufacturing process, for example, shrink fitting of motor rotors to shafts, shrink fitting of shell casings for compressors.

5. Coating: Of dissimilar metals, prior to insulation, and curing, such as paint.

6. Melting: Of all types of metals.

7. Other applications include crystal growing, cap sealing, sintering, carbon vapor deposition, levitation, exit axial deposition, and plasma generation.

Chengdu Jinkezhi Electronic Co., Ltd.

- Phone: +86 028-83968704

- Business Type: Manufacturer

- Location: China

- Main Products: Supersonic Frequency Induction Heating Machine,High Frequency Induction Welding Machine,Intermediate Frequency Furnace,Gold Melting Furnace

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue:

Recommended

-

Hot sales new type electromagnetic induction heater for bearingUSD 10000.00

Hot sales new type electromagnetic induction heater for bearingUSD 10000.00 -

100kg induction furnace for steel meltingUSD 10000.00

100kg induction furnace for steel meltingUSD 10000.00 -

Water cooling heat treatment steel bar induction quenching machineUSD 8000.00

Water cooling heat treatment steel bar induction quenching machineUSD 8000.00 -

MOSFET portable soldering brazing machineUSD 10000.00

MOSFET portable soldering brazing machineUSD 10000.00 -

Induction heater for Melting Hardening Bonding and ForgingUSD 3000.00

Induction heater for Melting Hardening Bonding and ForgingUSD 3000.00