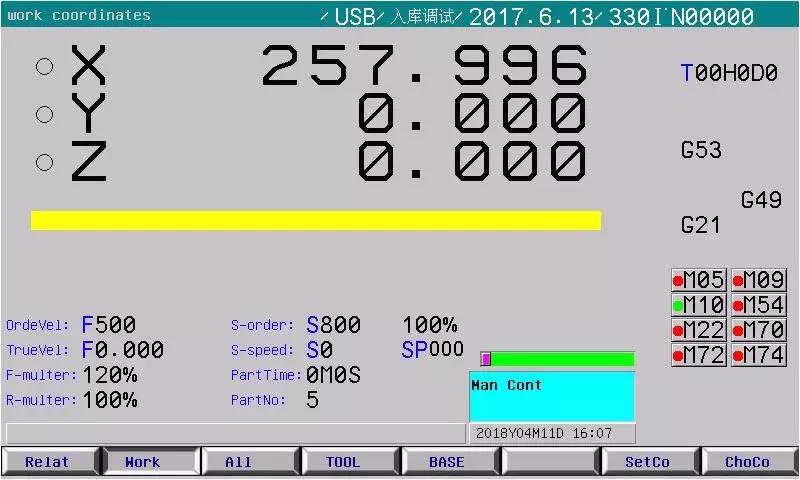

Smart 3 Axis Mill CNC Motion Control System Replace Siemens CNC Control System is our new Cheappest Engraving or Millig Machine CNC Control model designed specially for small budget and can maximum control 4axis, but standard configuration is 3axis. It adopts CPU with32 bits 400MHz ARM high capacity industrial grade composing a control core, and achieves the μm level accuracy motion control. It is characterized by multiple functions, stable and cost performance CNC Controller models and easy operation; Good Choice for Engraving and Universal milling machine .

Smart 3 Axis Mill CNC Motion Control System Replace Siemens CNC Control System | |

Motion control

| Control axes:X,Y,Z,4th(standard:3axis); linkage axes:3axes; PLC control axes: 4axes |

Interpolation function:X,Z two axes linear,arc and thread interpolation:X/Y two axes linear interpolation;2ms interpolation period and accuracy arrive to 1um, can set as 0.1um. | |

Max.rapid traverse speed:60m/min; Max.cutting speed:30m/min | |

Feed rate override:16-level real-time adjustment from 0-150% | |

Thread function:equal pitch straight thread/taper thread/end face thread, variable pitch straight thread types and thread retraction length, angle, speed can be set. | |

Pre acceleration/deceleration: the acceleration/deceleration after interpolation can select the linear or S type. | |

MST function | M function can be specified by address M, M function can be user-defined. |

Analog voltage output of 0v-10v in two channels ,support two spindles. Real-time adjustment of spindle rate and spindle encoder resolution; Adapted servo spindle can realize spindle continuous positioning, rigid and flexible tapping | |

T and 4 digits select the tool; Tool offset value setting;Tool length compensation; tool nose radius compensation (C type);tool wearing compensation | |

Automatic compensation | backlash compensation,pitch error compensation;tool length compensation,tool radius compensation |

Reliability and safety | State signals: emergency stop, overtravel ,stroke limit,servo ready signal, automatic run start light signal ,automatic running signal , feed hold light signal. Self-diagnosis function: signal abnormity, system abnormity,servo abnormity, position control abnormity, spindle abnormity and so on. NC alarm:program error, operation error, overtravel error, servo error, PLC error, memory error |

Operation function | Operation mode:edit, auto, MDI, machine zero return,MPG/step, Manual ,DNC,single block,Dry run, MST lock, orogram restart, MPG/step/Manual interruption; Machine lock, interlock , feed hold ,cycle start, emergency stop, external reset signal .external power ON/OFF.Program zero-return, Multi-level operation authorization management |

Chengdu Soteng CNC Technology Co., Ltd.

- Phone: +86 028-86623586

- Business Type: Manufacturer

- Location: China

- Main Products: CNC350iTa High Quality Computer Numerical Control 2 Axis Lathe CNC Controller

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: