LST Chocolate Enrobing Line with Cooling Tunnel

Product parameters

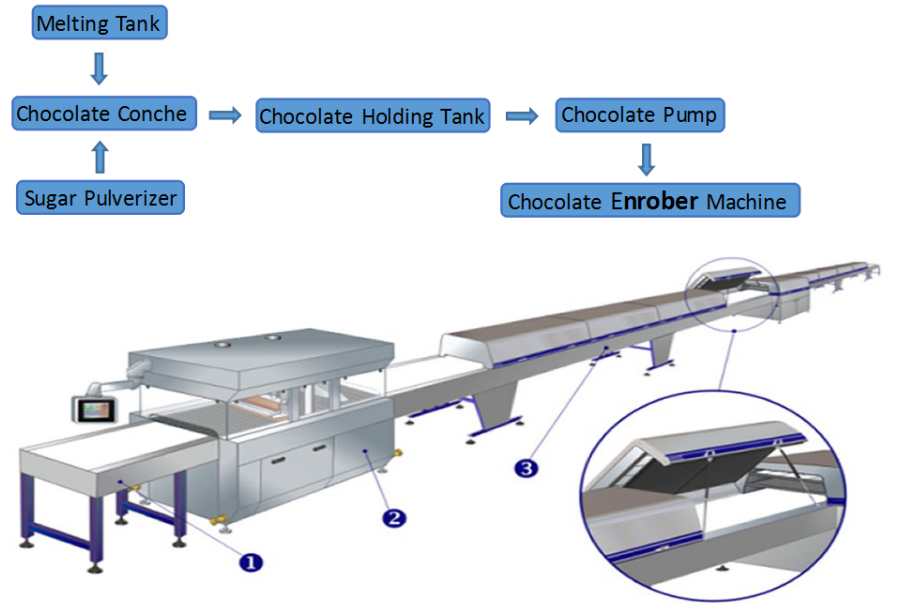

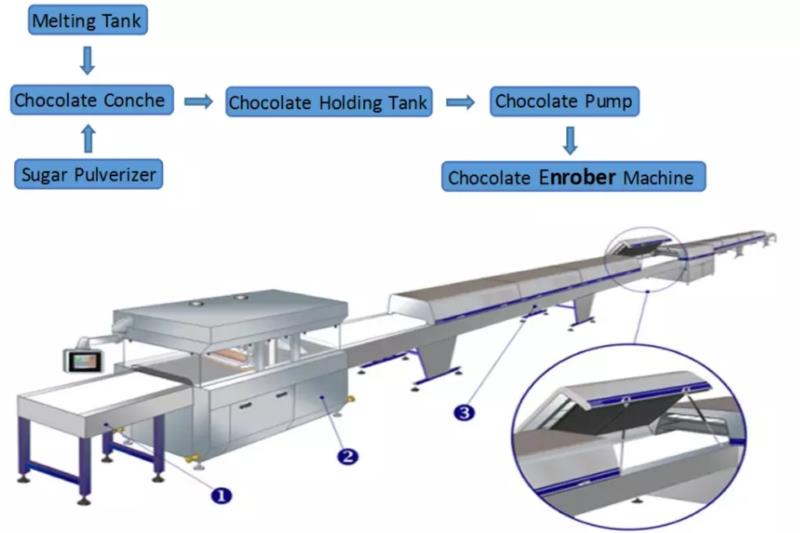

LSTChocolate Enrobing Line with Cooling Tunnel

The enrobing line is to coat chocolate on various food such as biscuit, wafers, egg rolls, cake pie and snacks etc..

Cooling tunnel and some special devices are optional.

1: Material feeder: to simplify the feeding of biscuits or wafers to the enrobing wire mesh .

2: Granular sprinkler :to sprinkle sesame or peanut granular on the enrobing products. (Add-on device)

3: Decorator :to decorate zigzags or stripes of different color on the surface of enrobing products.(Add-on device)

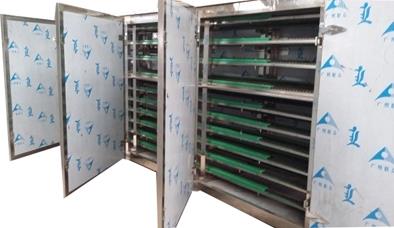

Cooling Tunnel

Air cooling tunnels are universally used for product cooling after molding. Such as filled candy, hard candy, taffy candy, chocolate and many other confectionery products. After conveying to cooling tunnel, products will be cooled by special cooling air. Cooling effect is stable and the whole process is clean. Import compressor from USA and frequency converter greatly improves the stability and durability of this device.

Features and Advantages:

1.Cooling tunnel are equipped with 2 sets of 5P refrigeration systems. Direct touch cooling on bottom side and indirect top cooling design.

2.All stainless steel and food grade conveyor belt which in compliance with food hygiene and safety standard.

3.Two stages or even more stages of cooling, such as fresh air cooling and refrigeration cooling,etc. The multi-stage cooling design makes it energy saving, fast cooling, easy operation,etc.

4.Tunnel cover adopts the latest design concept, fully covered and sealed design greatly avoid energy loss.

5.The tunnel cover can be opened or removed easily, no tools needed,easy for cleaning.

Chengdu LST Science And Technology Co., Ltd.

- Phone: +86 028-87395367

- Business Type: Manufacturer

- Location: China

- Main Products: full-automatic chocolate depositing machine,oatmeal chocolate molding machine,

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: