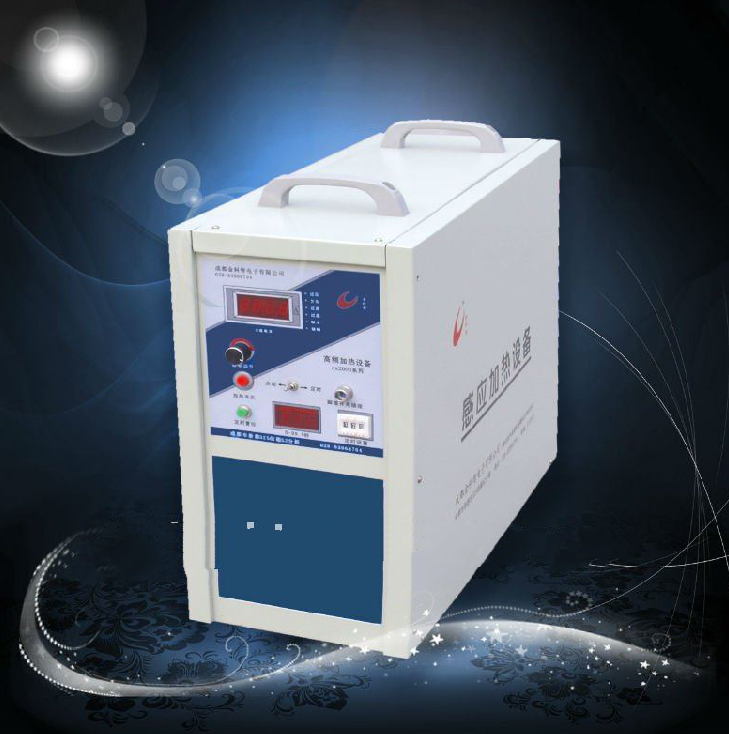

electromagnetic induction heating machine

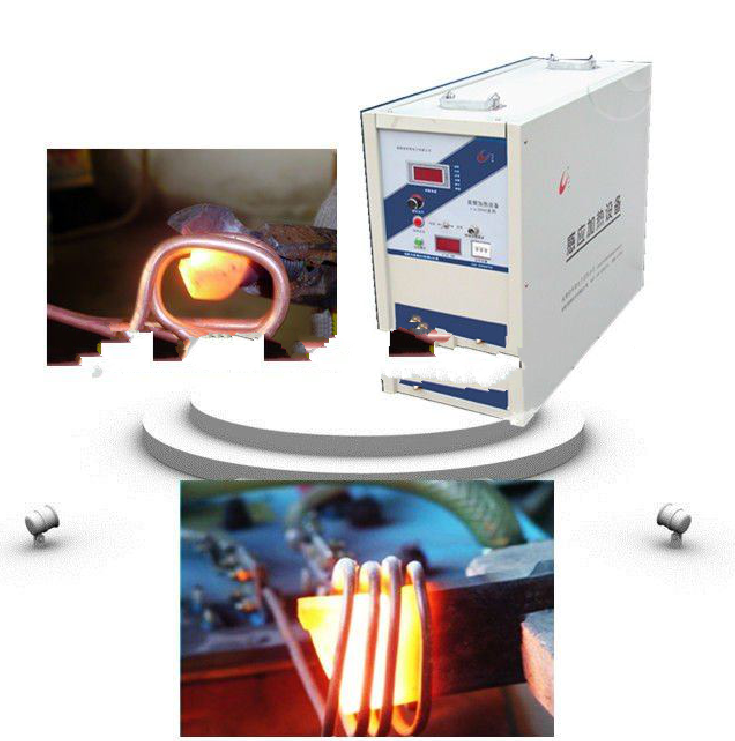

1. metal tube welding:

such as copper tube, steel tube, and aluminum tube’s butt welding, plug welding and

welding sets.

2. alloy cutter welding:

such as alloy turning, milling cutter, planer, saw blades, reamer, boring knife.

3. carbide saw blade welding:

diamond saw blade welding, marble saw blade welding,woodworking saw blade welding,

cut grass piece of welding, cut aluminum welding,

4. metal welding:

such as: towel rack, soap nets, towel holder, auto-accessories,

moto accessories, metal terminals, hardware pieces, electric heating tube parts and fasteners.

5. customized service:

make machine according to customers' actual working situation.

IGBT (SIEMENS) technology, high conversion efficiency; Energy saving 15%-30% , compared to SCR/KGPS technology

Much more efficient than gas-fired and coal-fired method

100% start-up success rate; power factor > 95%

Perfect and complete protection functions, increasing machine's reliability & stability

No special foundations required, Low operating cost, Easy operation

Modular design, ease of maintaining and repairing

Chengdu Jinkezhi Electronic Co., Ltd.

- Phone: +86 028-83968704

- Business Type: Manufacturer

- Location: China

- Main Products: Supersonic Frequency Induction Heating Machine,High Frequency Induction Welding Machine,Intermediate Frequency Furnace,Gold Melting Furnace

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: