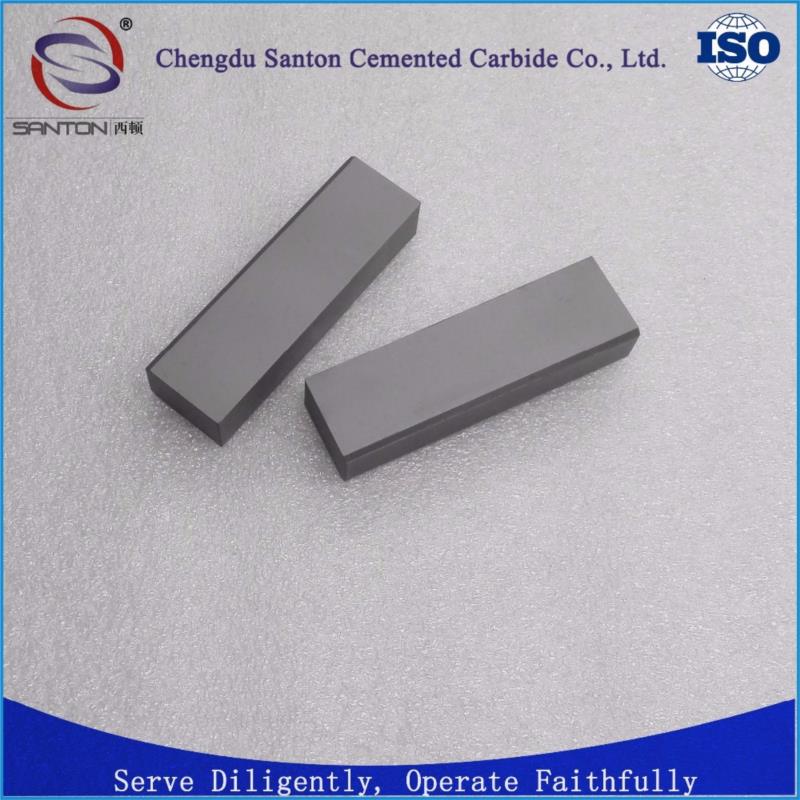

Product Description

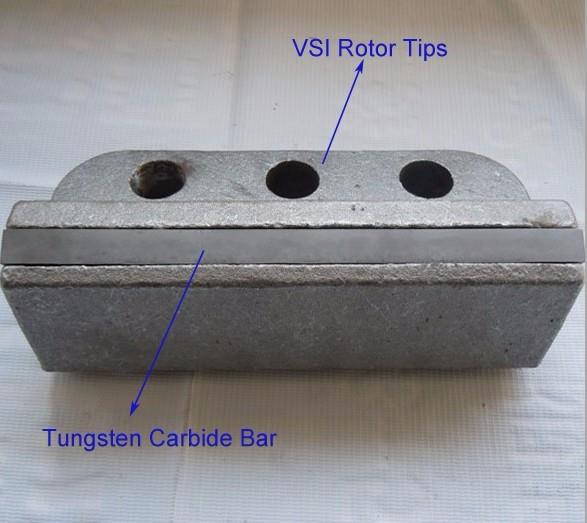

The tungsten carbide tips are used for stone cutting (marble,granite,hard stone) in the

quarry,it can fit for all kinds of chain saws.

Customized design is available here!

Feature

High quality and stability

High performance. dimensionally accurate

Good abrasive and corrosion resistance

High tensile strength

Easy welding, no crack or chipping

Application

Grade information

SantonGrade | ISO Grade | ANSI Grade | Physical and Chemical Property | Performance & Applications | ||

Density | TRS | Hardness | ||||

g/cm3 | n/mm2 | HRA | ||||

YT15 | P10 | C7 | 11.3 | 1650 | 92.0 | Higher wear resistance with a certain impact toughness, Suitable for semi-finishing of medium chip sections, or finishing of small chip sections of steel, cast steel, alloy steel. |

YT14 | P20 | C6 | 11.4 | 1750 | 91.5 | High strength, good impact and shock resistance. Suitable for rough turning, finish milling of carbon steel, and alloy steel during continuous cutting, and semi-finishing and finishing turning during interrupted cutting . |

YT5 | P30 | C5 | 12.9 | 2200 | 90.5 | Best strength, high impact and shock resistance among W-Co-Ti alloys, but comparatively lower wear resistance. Suitable for rough turning, rough planning, and semi-finish planning of carbon steel, and alloy steel including forgings, stamped parts, and cast iron surfaces during intermittent cutting. |

YW1 | M10 | _ | 13.0 | 1710 | 92.5 | Better red hardness, resistant to impact load. A good grade for general purposes. Suitable for machining of ordinary steel, cast irons as well as steels hard to be machined such as refractory steel, high manganese steel, and stainless steel, etc. |

YW2 | M20 | _ | 12.9 | 1880 | 91.0 | Higher wear resistance and strength, resistant to high impact load. Suitable for roughing and semi-finishing of ordinary steel, and cast irons as well as refractory steel, high manganese steel, and high-grade alloy steel, etc |

YG6X | K15 | C3 | 14.9 | 1890 | 91.5 | Fine grain WC alloy, wear resistance higher than YG6, strength close to YG6. Suitable for machining chilled alloy cast irons, and refractory alloy steel, as well as finishing of ordinary cast irons. |

YG6 | K20 | C2 | 14.9 | 2050 | 90.5 | High wear resistance, better impact and shock resistance. Suitable for semi-finishing, and finishing of cast irons, non-ferrous metal, alloys, and non-metallic materials at moderate cutting speed. |

YG8 | K30 | C1 | 14.7 | 2520 | 90.0 | High strength, better impact and shock resistance, but lower wear resistance and cutting speed. Suitable for roughing of cast irons, non-ferrous metal, alloys, and non-metallic materials at low speed. |

Chengdu Santon Cemented Carbide Co., Ltd.

- Phone: +86 028-85739522

- Business Type: Manufacturer

- Location: China

- Main Products: mining insert

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: